As the only single forming process in sheet metal processing, bending process is one of the most important processes in sheet metal processing. The quality of bending process will directly affect the forming size and appearance of products. Therefore, how to ensure the forming size and angle of the workpiece in the bending process is a key research content in the bending process.--Notching

According to the bending process, the size of the edge arc radius of the workpiece after bending is in direct proportion to the thickness of the plate. The thicker the plate is, the larger the arc radius formed by bending is. After the notching of the metal plate, the remaining thickness of the plate becomes half or even smaller, which can greatly reduce the edge arc radius after the workpiece is bent. In addition, due to the thin thickness of the remaining plate at the bend after notching, the deformation force during bending will be reduced accordingly, which will not diffuse and affect the non-bent area. Therefore, there is no crease on the surface of the workpiece after bending, and due to the thin thickness of the plate at the bend, the reduction of the pressure required during bending can well avoid the risk of indentation on the decorative surface. In this way, it can meet the process requirements of small edge arc radius, no crease on the surface and no indentation on the decorative surface in the metal decoration of high-end places such as hotels, banks, business centers and airports.

1. Generally, the machining of V-shaped groove is carried out when the customer has special requirements for the bending of sheet metal parts, and the normal bending cannot reach the minimum value required. At this time, use grooving and bending.

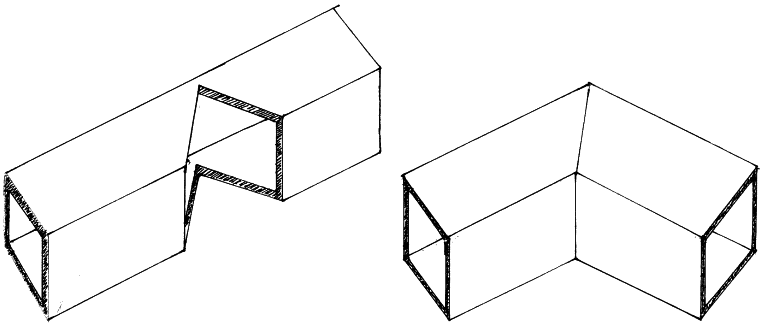

2. The structural dimensions of sheet metal parts are specially designed. When the normal bending cannot be reached, it is necessary to plane grooves. For example, for U-shaped structural parts, the inner cavity size is only a few millimeters. At this time, double V-grooves are used for forming.

3. Depth, width and angle of V-shaped groove

The depth of V-groove planed by materials with different thickness is different. The specific processing data depends on the customer's requirements for products.

Precautions: according to experience, the angle of V-groove planed should be 2 degrees larger than the actual forming angle. The material will rebound during bending and forming, and a gap of 2 degrees is reserved for controlling the angle during processing.

4. Aluminum plate notching

For aluminum plates that cannot be bent directly, slotting shall be carried out before bending. However, if the aluminum plate is grooved and then folded, it is bound to cause great damage to the strength and stiffness of the aluminum plate. Therefore, our company believes that the aluminum plate should be grooved only when it is not allowed, and the depth of the grooving should not exceed half of the thickness of the aluminum plate. Of course, after grooving, the bent fillet is small, generally R is about 1.5 ~ 2mm (depending on the depth of the grooving), while for the aluminum plate without grooving, the bent fillet R is generally 4 ~ 4.5mm (the thickness of the workpiece is 3mm).

Machining Scope:Precision Laser Cutting, Fiber Laser Cutting, CNC Robot Bending, Riveting, Welding, Broaching, Drilling, Tapping, CNC Machining, Metal Finishing, Assembling etc.