Is it cheaper to paint or powder coat?

In general, powder coating is more expensive upfront than traditional painting, but there are several factors to consider when determining which option is cheaper in the long run:

2024-09-03

Sheet Metal Welding Guidelines

Welding sheet metal requires special attention due to its thinness, which makes it more prone to warping, burn-through, and distortion. Below are key guidelines for welding sheet metal effectively:

2024-08-31

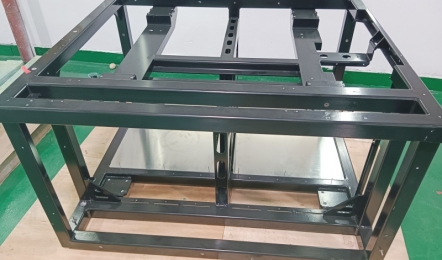

Metal Enclosure Design Tips

Designing a metal enclosure requires attention to several factors to ensure functionality, durability, and ease of manufacturing. Here are some key tips: 1. Material Selection Aluminum: Lightweight, corrosion-resistant, and good for heat dissipation. Steel: Stronger than aluminum but heavier; it can be galvanized or powder-coated for corrosion resistance. Stainless Steel: Excellent corrosion resistance and durability, ideal for harsh environments. Copper or Brass: Used for high conductivity requirements, though expensive.

2024-08-15

Sheet Metal Riveting Tips

Here are some tips for effective sheet metal riveting: 1. Material Selection Rivet Material: Ensure the rivet material is compatible with the sheet metal. Common materials include aluminum, steel, and stainless steel. Sheet Metal Thickness: Choose the appropriate rivet size for the thickness of the materials being joined.

2024-07-16

How to Avoid Sheet Metal Welding Defects?

Avoiding defects in sheet metal welding involves careful preparation, appropriate technique, and thorough inspection. Here are some strategies to minimize welding defects: 1. Proper Material Selection Quality of Material: Use high-quality sheet metal with minimal impurities. Appropriate Thickness: Ensure the sheet metal thickness is suitable for the welding process and application.

2024-06-29

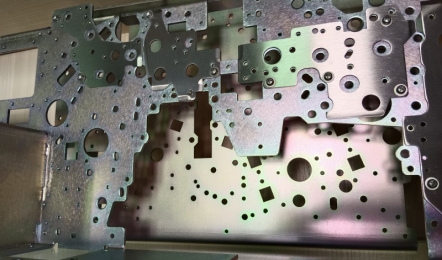

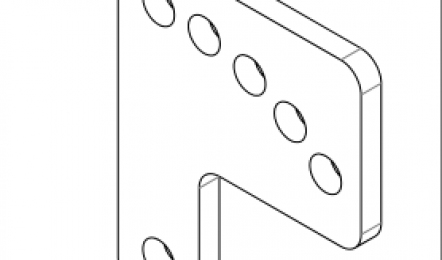

Process Analysis of Sheet Metal Structure Design

Sheet metal processing is a comprehensive cold working process for sheet metal, including shearing, punching, cutting, folding, welding, riveting, etc. its remarkable feature is that the thickness of the same part is the same.

2022-08-22

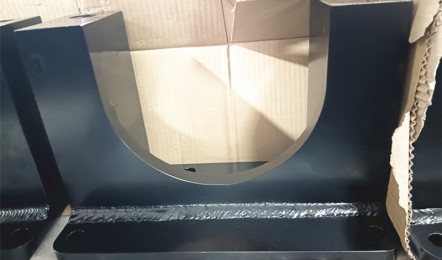

Methods to Prevent Corrosion of Sheet Metal Enclosure

In the production of sheet metal shell, sometimes no matter what material we use, the sheet metal shell may be corroded after long-term use due to the problem of wet weather. When this phenomenon occurs, it will undoubtedly cause great inconvenience to us.

2022-08-20

Advantages of Laser Welding of Sheet Metal Cabinet

The production process of the processing industry of sheet metal chassis and cabinets has developed rapidly. In the welding operation of chassis and cabinets, there are mostly strict welding requirements, such as welding slag, deformation, burn through, bulge and depression are not allowed. The welding requirements are neat, uniform, firm and reliable. With the popularization of laser cutting machine, the accuracy of sheet metal cutting and blanking is getting higher and higher, which also creates conditions for the application of laser welding machine technology. Many sheet metal processing enterprises began to consider using laser welding machine technology to improve welding accuracy and aesthetics.

2022-08-11

How to Select the Processing Method of Sheet Metal Parts?

The weight of sheet metal processing parts is relatively light, but the strength is high and the conductivity is good. The important thing is that the cost is relatively low. If a large number of large-scale production has good performance, processing can improve the function and service life of products. Of course, we all know that processing skills are indeed a little troublesome, but the processing of sheet metal chassis shell can bring greater benefits to enterprises, so there are so many reasons for selective processing.

2022-08-11

Automatic Stamping

Discussion on automatic stamping is a common production method.

2022-08-11

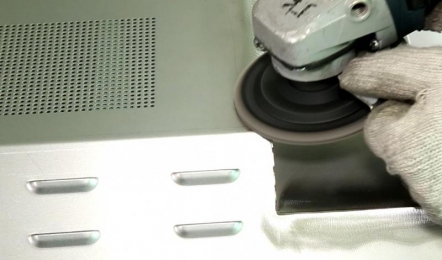

Four Basic Cold Processing Links to Optimize Sheet Metal Design

Generally, sheet metal parts have obvious advantages in strength, weight and cost, and have better point-to-point performance than traditional parts. Therefore, up to now, sheet metal parts have been gradually applied in China’s high-tech fields such as electronics and communication. At the same time, people have gradually put forward higher requirements for the quality and function of sheet metal parts, The proper optimization of the original sheet metal processing technology has become the focus of sheet metal processing personnel. According to the actual research, this paper believes that the optimization of processing technology should be carried out one by one from the application of four basic cold processing links of sheet metal processing.

2022-08-10

Reduce the Deformation of Sheet Metal Welding With the Help of External Force

1 Water cooling block Many techniques can be used to control the welding deformation of special welding workpieces. For example, in thin plate welding, the use of water-cooled blocks can take away the heat of the welded workpiece. The copper pipe is welded to the copper fixture by brazing or tin welding, and the circulating cooling is carried out through the water pipe to reduce the welding deformation.

2022-08-09