The Way of Avoiding Sheet Metal E-coating Defects

E-coating (electrocoating) is a crucial process in the sheet metal industry used to apply a protective and often decorative coating to metal surfaces. Despite its effectiveness, a variety of defects can occur during this process. Below is a comprehensive guide to possible E-coating defects, their causes, and potential remedies:

2024-07-19

Israeli Customer Visit Plant and Guide Work On-site 23th June.

Strategic Cooperation was started with new valued Israeli Client, through audit on-site, meeting discussion face to face, both parties had a better and deep understanding each other to laid a solid foundation on the mutual business partnership for a long-term.

2023-07-03

How to Weld Aluminum and Aluminum Alloy with TIG Welding?

TIG welding, also known as tungsten inert gas shielded arc welding, uses the large amount of heat generated by the arc formed between the tungsten electrode and the workpiece to melt the area to be welded, plus filler wire to obtain a solid welded joint. Argon arc welding of aluminum uses its “cathodic atomization” feature to remove the oxide film by itself. The tungsten electrode and the seam area are protected by a shield of inert gas emitted from the nozzle to prevent reaction between the weld area and the surrounding air.

2023-04-11

What are the Applications of Aluminum Box?

An aluminum box is a custom-made metal container that is typically used to store or transport items. They can be made in a variety of sizes and shapes, and can be customized with features such as reinforced corners, hinges, locks, and other hardware to meet specific needs.

2023-02-13

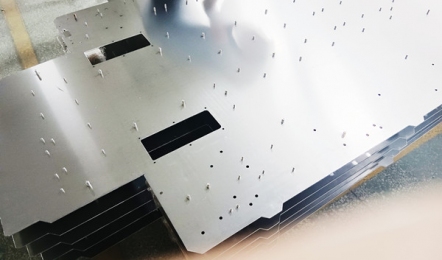

Creating Sheet Metal Boxes: A Step-by-Step Guide to Folding

Custom sheet metal boxes are a versatile way to store and protect items. They are widely used in industrial, commercial and residential applications. With custom sheet metal boxes, you can create the perfect size and shape to fit the item you need to store. This article will guide you through the steps of creating custom sheet metal boxes and the techniques used to make them.

2023-02-10

What is the General Tolerance for Sheet Metal Fabrication?

Sheet metal processing is the most commonly used metal processing method nowadays. In the process of parts processing, the size of produced sheet metal parts cannot be absolutely accurate due to various factors such as processing accuracy of machinery and equipment, die wear and tear, processing errors, etc. In order to ensure the availability of the workpiece, we must limit the tolerance of the sheet metal workpiece to the minimum. So what are the common tolerance standards in sheet metal processing? How should they be marked? Today, we will share them with you.

2023-01-31

How to Choose the Right Material for Sheet Metal Parts?

The effect that can be brought out in precision sheet metal differs from one material to another, ranging from ordinary cold-rolled sheet to composite precision sheet metal. This is because the degree of processing and the material used will affect the effect of the whole sheet metal. Generally speaking, the two main criteria for judging the standard of precision sheet metal are the anti-corrosion type and wear resistance. Then how to choose the right material for precision sheet metal processing?

2023-01-31

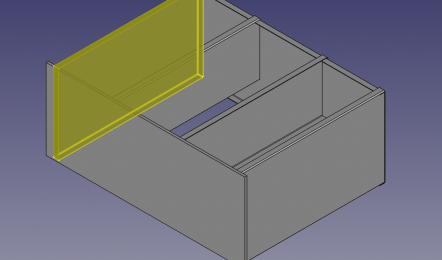

How Do You Fold a Sheet Metal Box?

6 types of bending and forming of sheet metal Bending forming of sheet metal is when the sheet metal first goes through elastic deformation and then enters plastic deformation under the pressure of the upper or lower die of the bending machine. At the beginning of plastic bending, the sheet is free to bend. With the pressure of the upper die on the plate, the plate and the lower die V-groove surface gradually tighten, while the radius of curvature and bending force arm also gradually become smaller. Continue to press until the stroke is terminated, so that the upper and lower die and the plate are in full contact at three points, at which time a V-bend is completed and a bend is formed.

2023-01-31

Sheet Metal Design Guide - Considerations for Sheet Metal Parts

Sheet metal is one of the design types that we are most exposed to on a daily basis and has a complex design process. As sheet metal is widely used, sheet metal design has become an important part of product development, so what do you need to pay attention to during the sheet metal design process? Here's what Muvot introduces to you.

2022-12-29

What are Main Welding Methods that Sheet Metal Worker Commonly Use?

What are the main welding methods commonly used by sheet metal workers? Arc welding The heat generated by the arc discharge is used to melt the electrode and the workpiece and form a weld after condensation to obtain a firm joint.

2022-12-12

What is Surface Treatment? Why Should Surface Treatment be Carried Out?

1) What is Surface Treatment? Surface treatment: change the shape, chemical composition and organizational structure of the product surface and near surface area by the most economical and effective method, effectively improve and improve the decorative performance(Decorative sheet metal cabinet), corrosion resistance and wear resistance of the product, and prolong the service life of the product.

2022-08-29

Welding Process

The defects must be completely removed before welding, and the groove surface shall be flat and smooth without sharp corners. According to the defects of steel castings, the defects in the welding area can be removed by shovel excavation, grinding, carbon arc air gouging, gas cutting or machining.

2022-08-26