1 Water Cooling Block

1 Water Cooling Block

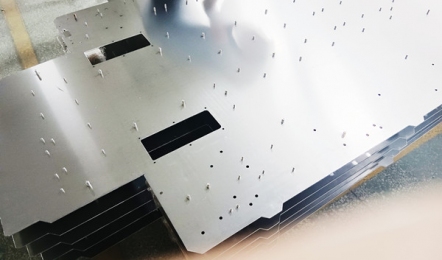

Many techniques can be used to control the welding deformation of special welding workpieces. For example, in thin plate welding, the use of water-cooled blocks can take away the heat of the welded workpiece. The copper pipe is welded to the copper fixture by brazing or tin welding, and the circulating cooling is carried out through the water pipe to reduce the welding deformation.

2 Wedge Block Locating Plate

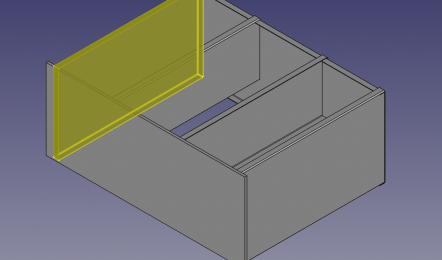

“Locating plate” is an effective technology to control welding deformation during butt welding of steel plate, as shown in the figure. One end of the positioning plate is welded on a plate of the workpiece, and the other end wedges the wedge block into the pressing plate. Multiple positioning plates can even be arranged to maintain the positioning and fixation of the welded steel plate during welding.

3 Thermal Stress Relief

Except for special cases, it is not a correct method to eliminate stress by heating. Welding deformation shall be prevented or reduced before the completion of workpiece welding. click here to contact JIATONG

QUICK LINKS:>>>Sheet Metal Frame | Sheet Metal Housing | Sheet Metal Chassis | Sheet Metal Cover | Sheet Metal Parts Components | China Sheet Metal Manufacturer | Custom Sheet Metal Parts | Sheet Metal Cabinet | China Sheet Metal Parts | Sheet Metal Bracket | Sheet Metal Parts Manufacturer | Custom Electrical Enclosures | China Sheet Metal Fabrication | China Metal Parts Manufacturer | Order Custom Metal Parts | Custom Machined Metal Parts | Sheet Metal Fabrication China | Metal Manufacturing in China | Metal Enclosure Manufacturers | Sheet Metal Cover | Sheet Metal China