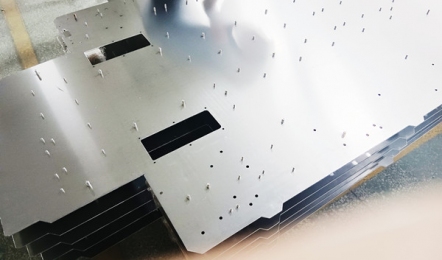

Sheet Metal Design Works, You Need to Know These!

1. Basic principles:

a. The principle of uniform thickness of products

b. Easy to Flatten Principle

c. Appropriately select the thickness of sheet metal parts

e. In line with the processing technology

https://sheetmetalxj.blogspot.com/

2. Process requirements:

A.Punching: ordinary punching and precision punching Note: Avoid narrow and long cantilevers and groove A with a thickness of not less than 2T.

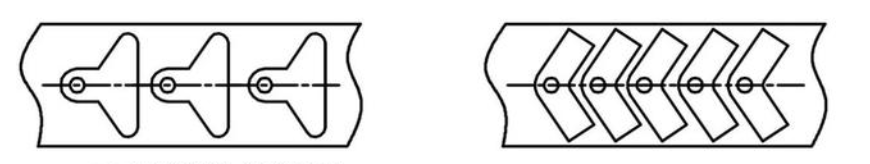

B.The width is not less than 1.5T punching: ordinary punching and precision punching b. The shape of the stamping parts should try to minimize the waste during layout. One material wasted and the other Saved as below.

Note:Under the circumstance that the use function can be achieved, plan B is preferred

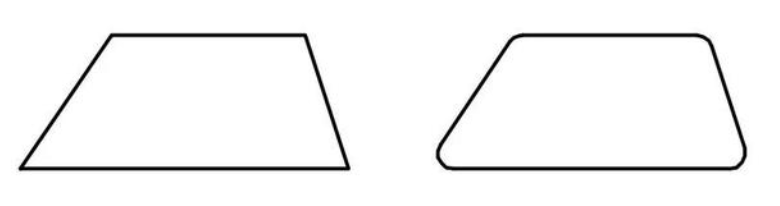

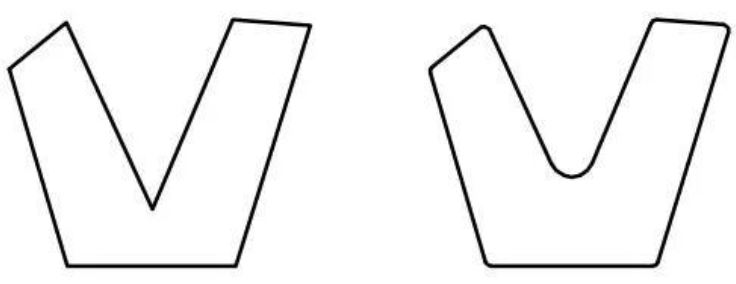

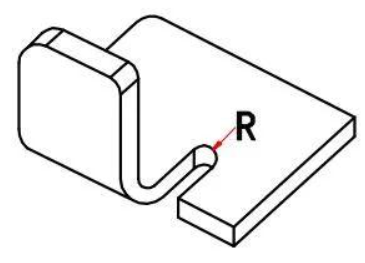

C.The shape and inner hole chamfering of stamping parts should avoid sharp corners

Note: sharp corners affect the life of the mold, the fillet radius R>=0.5T

D. Holes of stamping parts

≥1.3T

Material

Hole Diameter

Square Hole Width Short Side

SPCC, SECC, SGCC, SUS

≥1.2T

LOW CARBON STEEL H62, H65 BRASS

≥1.0T

≥1.0T

ALUMINUM

≥0.8T

≥0.6T

Note:The round hole is preferred, and the diameter of the punching hole should not be too small due to the impact of the strength of the punch.

E. Avoid sharp corners

Note: sharp corners affect the life of the mold, the fillet radius R>=0.5T

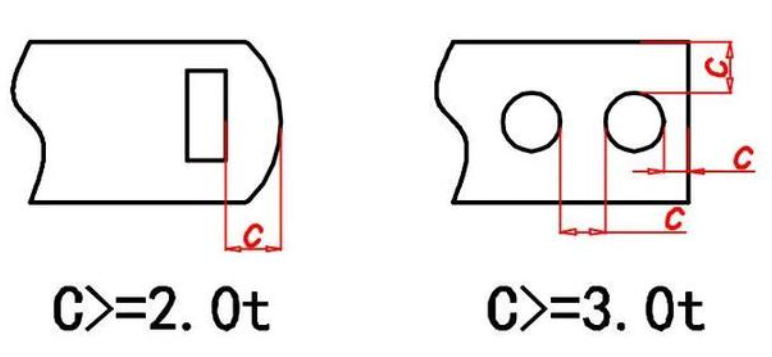

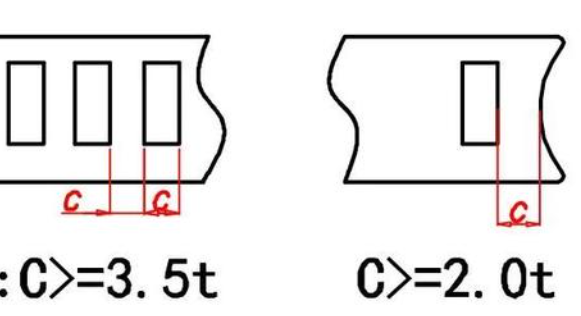

F. Hole spacing and hole edge distance of stamping parts.

Minimum Distance

G. The distance between the stamping part and the drawing part hole to the straight edge

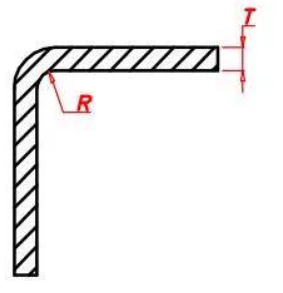

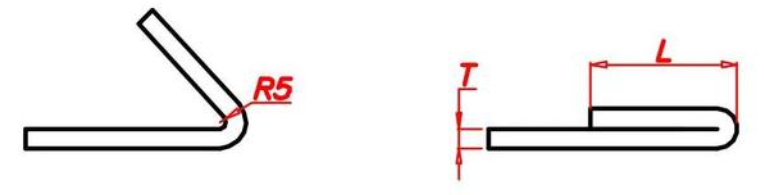

H. Minimum bending radius

| Material | Rmin |

| SPCC, SECC, SGCC | R ≥ 2.0T |

| LOW CARBON STEEL H62, H65 BRASS |

R ≥ 1.0T |

| SUS |

R ≥ 1.5T |

| ALUMINUM |

R ≥ 1.2T |

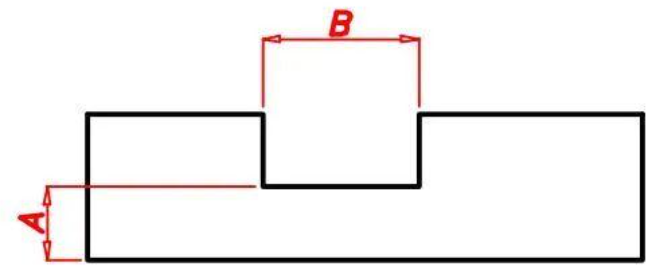

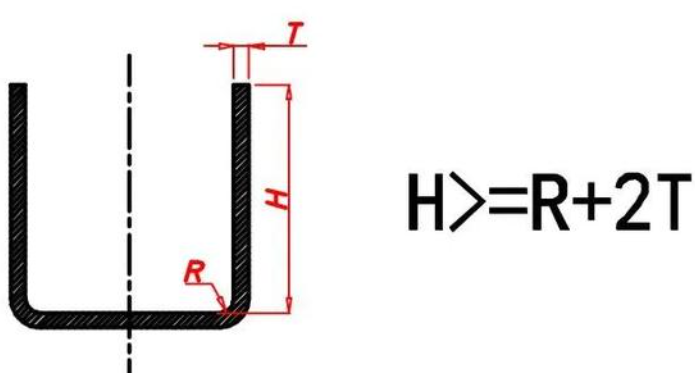

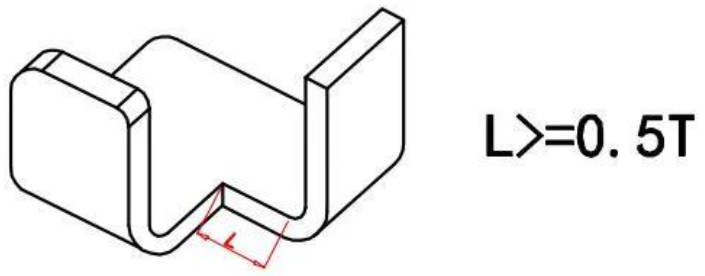

I. Straight edge height of bending part

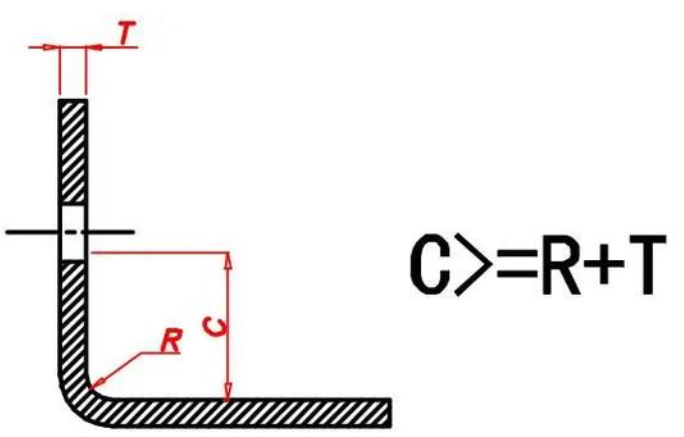

J. Minimum hole margin for bending parts

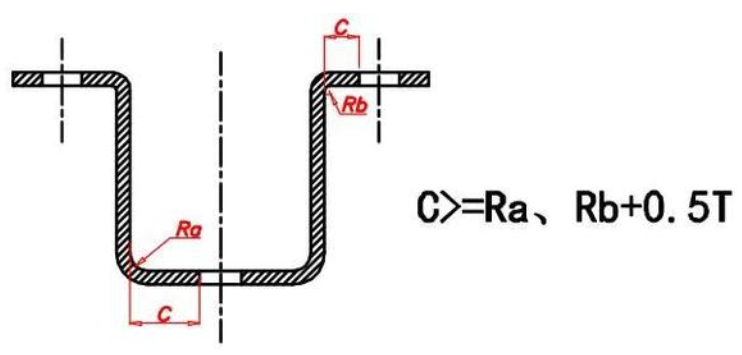

K. The bending edge and the rounded corner should keep a certain distance

L. Process notch design of bending parts

Note: Design of crack relief groove: width not less than 1.5T, depth not less than 2.0T+R

M. Design of the dead edge of stamping parts.

Note:The length of the dead edge is related to the thickness of the material. Generally, the minimum length of the dead edge is L>=3.5T+R

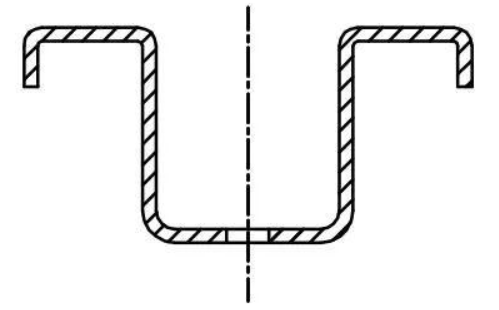

N. process hole design of stamping parts

Note:When designing U-shaped bending, it is better to have the same length on both sides. If the two sides are not allowed to be the same length due to structural requirements, in order to ensure accurate positioning in the mold, process holes should be designed.

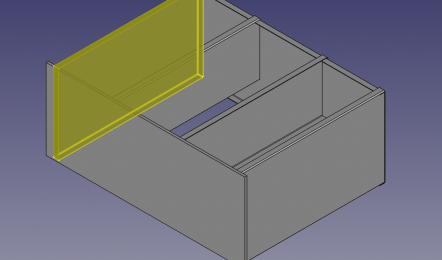

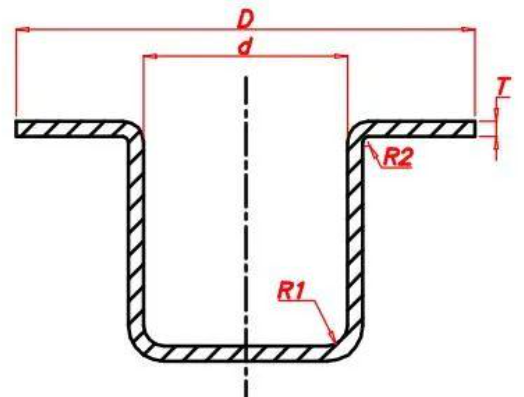

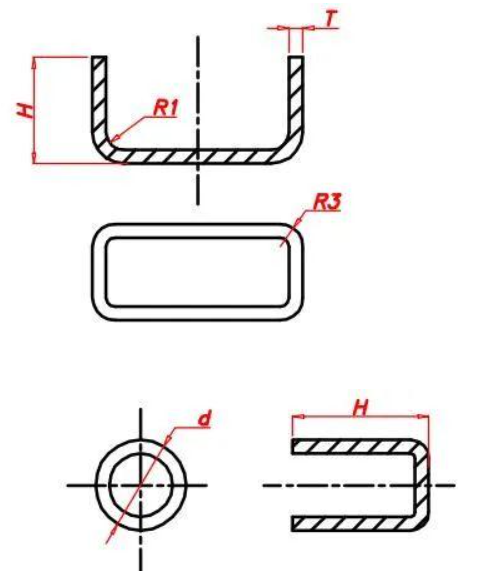

O. Design of Drawn/Stretched parts

Note:The design of the tensile part is as simple as possible, and the shape is as symmetrical as possible. R1 is about = (3~5) T R1min>=T R1max<=8T

Note:When the stretched part is stretched once without flange, the relationship between H and d is H=0.4d.

Friendly Links: https://www.sheetmetalxj.com/ | https://metalchassis.com/ | https://sheetmetal-supplier.com/ | https://sheetmetal-enclosure.com/ | https://sheetmetalcover.com/ | https://sheetmetal-chassis.com/ | https://mounting-bracket.com/ | https://customsheetmetal.cn/ | https://custombrackets.top/ | https://sheet-metal.wiki/ | https://sheetmetalparts.wiki/ | https://sheetmetalxj.blogspot.com/