Battery Cabinets

Sheet metal is generally some sheet metal through manual or die stamping to produce plastic deformation to form the desired shape and size, and can further form more complex parts through welding or a small amount of machining. For example, chimneys, iron buckets, oil tanks, oil pots, ventilation pipes, funnel-shaped, etc. commonly used in families, as well as electrical cabinets, shells of various special equipment, computer cases, automobile shells, etc., are all sheet metal parts.

2022-08-24

Price Comparison of Sheet Metal Parts

In the case of the same thickness: hot rolled plate < cold rolled plate < hot zinc plate < electric zinc plate < SD steel plate < stainless iron < stainless steel, the same materials, generally belong to the situation that the greater the thickness, the lower the price In the cost of sheet metal parts, the material cost basically accounts for 60-70%, sometimes higher Therefore, it is necessary to design a reasonable structure and improve the utilization rate of materials If the material utilization rate is low, the product price may be lower than the waste price III The purpose of steel plate surface treatment is to achieve the purpose through surface treatment because some sheet metal materials do not have the ability of rust prevention and corrosion prevention.

2022-08-23

What is the Scope of Sheet Metal Fabrication?

Custom Laser Cut MetalThere are many types of processing methods involved in the metal processing industry, and sheet metal processing is one of the more common processing methods. During the processing and production, the staff need to learn the processing technology first, so as to ensure the processing quality of the material and degree of processing.

2022-08-19

What Is Important for Sheet Metal Manufacturing?

Generally speaking, the equipment of sheet metal processing plant includes plate shears, CNC punches, laser plasma, water jet cutting machines, compound machines, bending machines and various auxiliary equipment, such as uncoilers, leveling machines, deburring machines, spot welding machines, etc.

2022-08-19

Custom Aluminum High Strength Sheet Metal Parts

Because designers cannot get rid of the design idea of machining structural parts, in order to improve the design strength of sheet metal parts, they blindly increase the thickness of sheet metal materials, but cannot improve the design strength from the aspects of sheet metal stamping process and bending process. When designing a sheet metal product, materials with the same thickness should be selected as far as possible, which can play a positive role in the production material preparation, processing, welding and other technological processes.

2022-08-19

Problems to be Considered in Structural Design of Sheet Metal Fabrication

The following issues shall be considered in the design of sheet metal processing structure: 1 It is necessary to consider the realization of product functions and its economy and practicality.

2022-08-19

Principles of Design and Installation of Metal Cabinet

1 In the principle of convenient installation, the hanging beam is adopted, which is convenient and flexible for installation and movement.

2022-08-19

Common Problems in Bending Process

Sheet metal manufacturers generally have many kinds of processes, and bending process is one of them, which is often used. Problems are inevitable in this processing process. Then I will introduce you how to solve the problems encountered in the bending process.

2022-08-18

Sheet Metal Design Feature

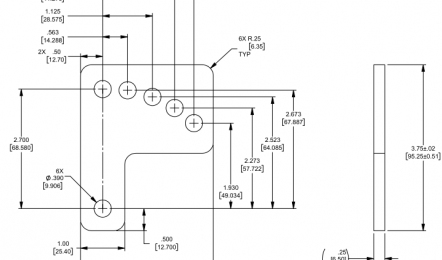

The features have the nature of parameterization, and their features are expressed in the way of parameters. Engineers establish a feature library in advance, which includes the features of parts commonly processed by sheet metal, such as flat plates, holes and grooves of various methods. Planning is to first input all the information of parts, select the matrix features in the feature library, generate matrix features, and take this as the basis for feature equipment modeling.

2022-08-17

Design Criteria of Sheet Metal Structure

According to the problems encountered in the actual machining process, the problems needing attention in the structural design of sheet metal are discussed from the following aspects, and the corresponding design criteria are given.

2022-08-16

Electrical Control Cabinet

The chassis of industrial control case has the advantages of extrusion resistance, corrosion resistance, dust resistance, vibration resistance and radiation resistance. It is mainly used in harsh environment. Such as power plants, chemical plants, mining plants, underground operations, etc. The computer chassis is the house of the computer host, which plays an important role in accommodating and protecting computer accessories such as CPU.

2022-08-15

Sheet Metal Electrical Cabinet Design Reference

Sheet metal generally deforms some metal sheets by hand or die stamping to form the desired shape and size, and can further form more complex parts through welding or a small amount of mechanical processing, such as chimneys, iron barrels, oil tanks, ventilation pipes, funnel shapes, etc. commonly used in families, and also such as electrical cabinets, shells of various special equipment, computer cases, automobile shells, etc. are sheet metal parts.

2022-08-15